SunHydrogen panels are more environmentally friendly than conventional hydrogen production methods and are also cheaper to install and transport.

SunHydrogen has officially announced that it has begun manufacturing and testing new large-scale panels that convert solar energy into hydrogen. In parallel, the company is working to protect the panels from chemical corrosion. In addition, SunHydrogen is completing site preparation for large-scale demonstration pilot plants.

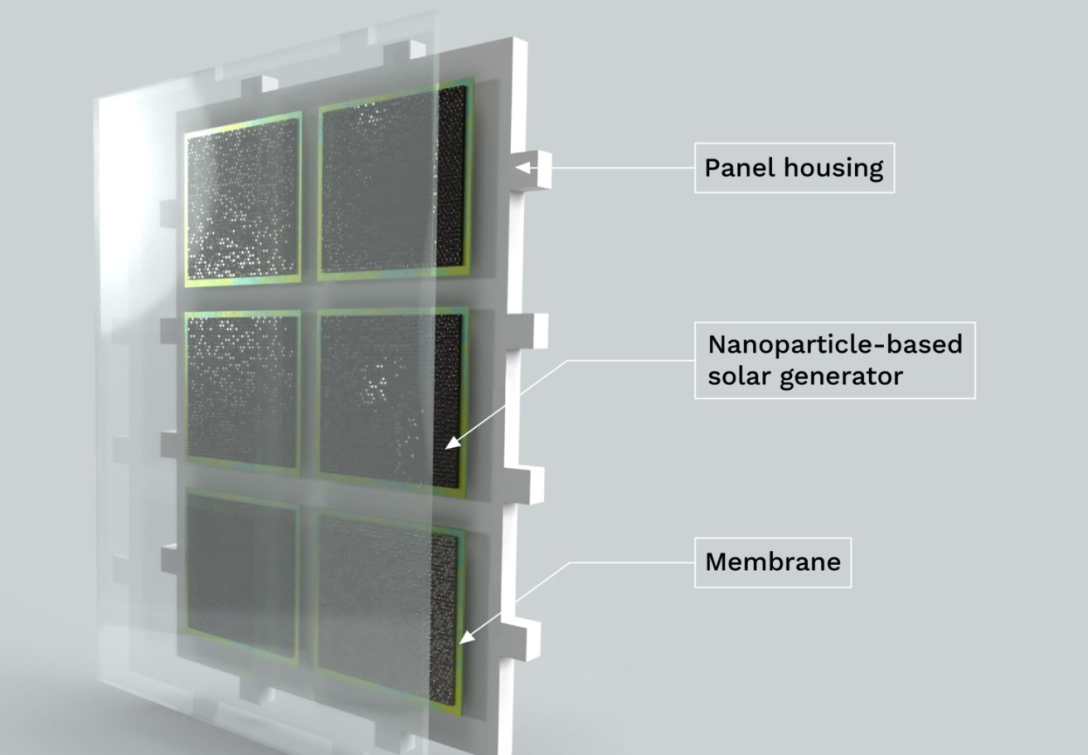

It is also reported that SunHydrogen specialists have developed innovative membrane-free housings for hydrogen panels. They will allow safe separation of hydrogen and oxygen without membranes, significantly reducing costs and eliminating the use of fluorinated compounds.

Previously, 100 cm² SunHydrogen hydrogen panels were tested at Honda’s research center in Japan, demonstrating an efficiency of 10.8% in converting solar energy into hydrogen.

“To our knowledge, no other company has achieved this level of efficiency using cost-effective semiconductor materials immersed in water,” said SunHydrogen chief scientific officer Dr. Syed Mubin.

SunHydrogen’s website says the technology could revolutionize the current energy economy, including transportation, industry, and shipping, which rely heavily on fossil fuels. The company says hydrogen solar panels could be mass-produced and deployed around the world, either locally or in large farms.

As the manufacturer notes, current methods of hydrogen production are environmentally unsafe. Almost all hydrogen today is produced using fossil fuels such as oil, coal and natural gas, which increase carbon emissions. In addition, the widespread implementation of traditional electrolysis technologies is expensive.

In turn, SunHydrogen panels are free of these disadvantages. The development has a zero carbon footprint and requires less investment in transport and delivery. The technology directly uses the electric charges created by sunlight to generate hydrogen, so ours does not depend on the power grid and does not require expensive power electronics, like conventional electrolyzers.

|

|

“The SunHydrogen method is efficient, cost-effective and truly environmentally friendly. The future is now,” the company claims.

Recall that the Chinese company China Petroleum & Chemical Corporation presented its pilot project Green Hydrogen for the production of hydrogen using solar energy in China. The facility combines solar power plants and advanced systems for the production of hydrogen, its storage and transportation.

In turn, in the USA there is an initiative for the production of hydrogen SoHyCa l, which also provides for the production of hydrogen through electrolysis, completely provided by renewable energy sources.

https://focus.ua/digital/674425-budushchee-uzhe-nastupilo-kak-vodorodnye-solnechnye-paneli-izmenyat-energetiku-foto